The Twenty-First Century Will Sees Growing Competition For Automotive Parts

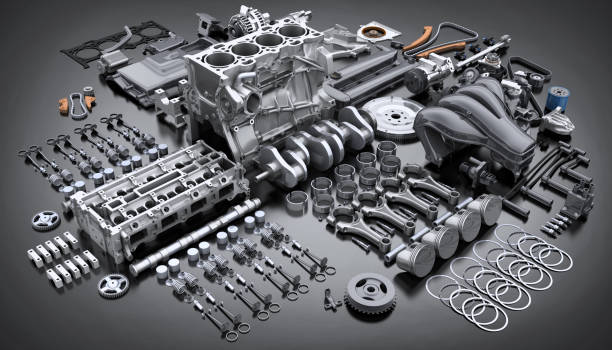

June 8, 2021Auto parts may be referred to as anything that is attached to an automobile and is used to make it run. There are two kinds of suppliers of auto parts: internal combustion engines and externally powered by gasoline or diesel. Since auto parts are not mere accessories but are functional systems that perform specific functions, there are different types of suppliers. The first type refers to the major manufacturers like Mercedes, BMW, Chevrolet etc. The second type refers to small companies that specialize in particular segments like performance cars or race cars. Each segment has its own suppliers like transmission and clutch components for trucks, cylinder heads and valves for motorcycles and camshafts for racing bikes.

Like car making, the automotive industry too is globalized. Many suppliers work worldwide, apart from Antarctica. Globalization has drastically changed the market especially in countries where domestic makers have been severely under pressure from overseas suppliers. The global expansion of the automotive industry has initiated consolidation of auto parts production plants as multinational companies have acquired significant positions in the global markets.

In the first half of the twentieth century, automobile components were produced and shipped in U.S. ports by way of long, arduous journeys via trucks. The major drivers of the U.S. economy at that time were agriculture, railroads, steel, oil and aviation. The Japanese automotive industry, on the other hand, started assembling its products in the United States after World War II. Since the U.S. automotive industry was based on Ford Motor Co, all its products were American-made and its biggest customers were U.S. citizens. By the mid 1960s, Japanese car makers had come to rely on transnational suppliers because they could easily ship their finished products across the Atlantic and Pacific oceans. Today, auto parts suppliers are also working with truck manufacturers and fleets.

Today’s global economic crisis, though, has made multinational auto parts companies reconsider their strategies. The growing complexity of the task has made them think again about their strategies. The emerging economies of Asia, South America and Central America have proven a strong demand for U.S. made parts. These emerging economies can offer the best prices and convenience to truck and car owners across the United States.

The globalization trend has increased the need for internationally approved automobile parts. Automotive manufacturers are now designing and engineering vehicles that can run on foreign engines with international standards. They have started to produce cars and trucks using Japanese, Brazilian, Mexican and Indian parts. The emergence of these Asian nations as viable outsourcing destinations has made the U.S. auto parts market more competitive. With the success of the transnational companies, the U.S. manufacturing base has expanded and the domestic automotive industry has become a victim of global competition.

The auto parts industry is witnessing intense competition in the next decade. Rising labor costs in Asia-Pacific countries and a burgeoning new market in Latin America will push suppliers to improve their products and services. Companies will find it increasingly difficult to sustain their current levels of production. As a result, many of these companies will either merge or seek to acquire other companies that currently produce lower quality, less competitive auto parts.